Product Features

Our slurry pump is designed for the most abrasive slurry pumping applications in mining

Our UMD horizontal pump is ideal for ball mill discharge, highly abrasive slurry applications in hard rock mining and oil sands.

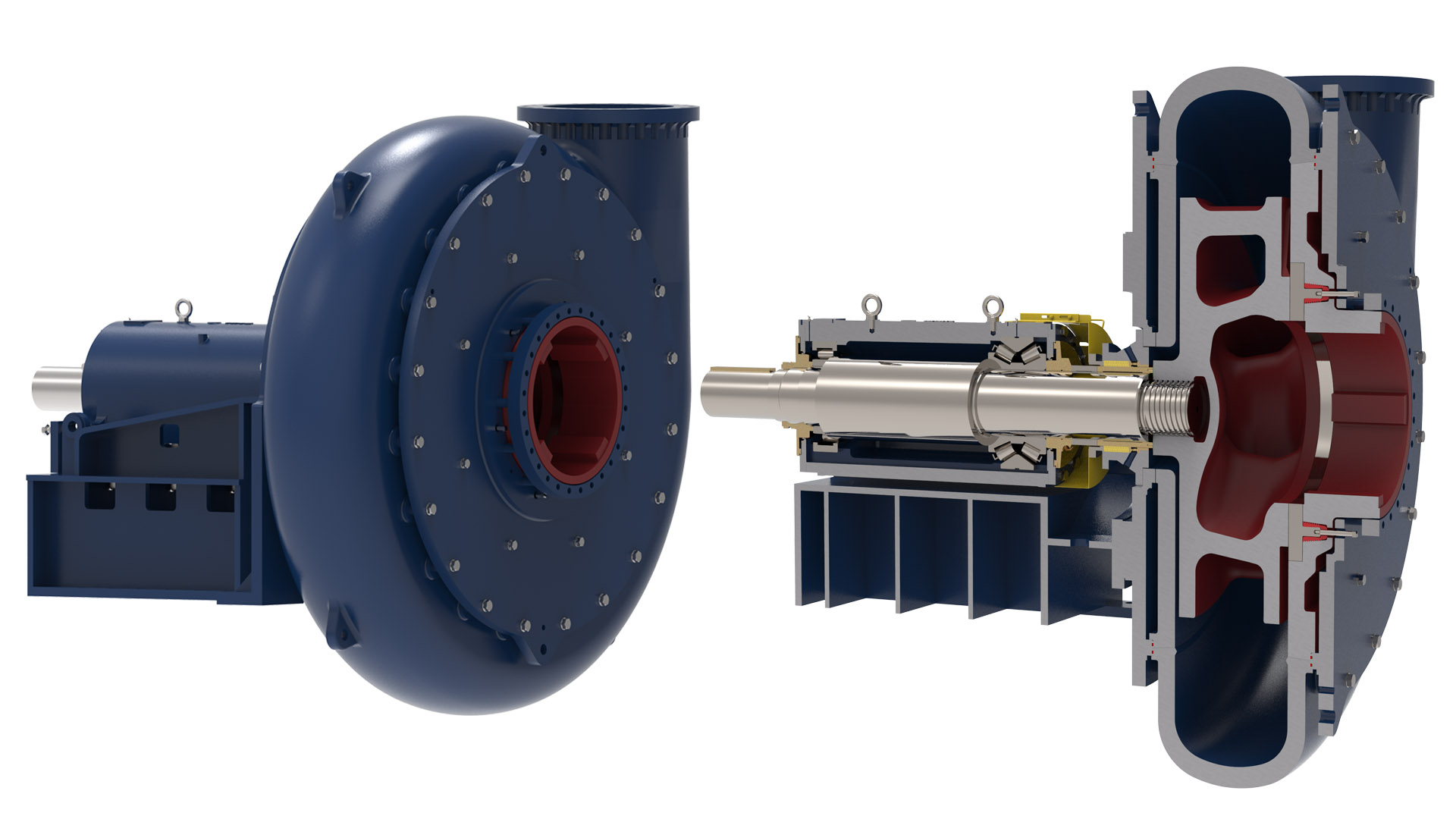

Pumping the discharge from hard rock grinding mills is one of the most high-wear applications due to high concentrations of abrasive solids. Conversely, the hydrotransport process in oil sands deals with a range of particle sizes from very coarse sand and heavy lumps to fine clay and coarse silica sand. Our UMD pump was designed specifically for these highly abrasive and diverse particle size applications. By integrating a superior hydraulic design and the patented millMAX suction-side sealing system, the UMD maximizes wear life and increases efficiency.

Wide range of options

Unique design for a wide range of options

The impeller features optimized pumping vane shape, increased shroud diameter, and improved expelling vane shape to bring you the most hydraulically advanced impeller of its kind. The design also accommodates fine solids with durable, replaceable and less expensive liners. We extended the back liner and suction liner diameters to reduce wear and improve performance.

The UMD includes a wide range of pump sizes that can handle flows from 50 to 20,000 cubic meters per hour (200 to 90,000 gallons per minute). The UMD high-pressure models are also available for multistage high-pressure applications.

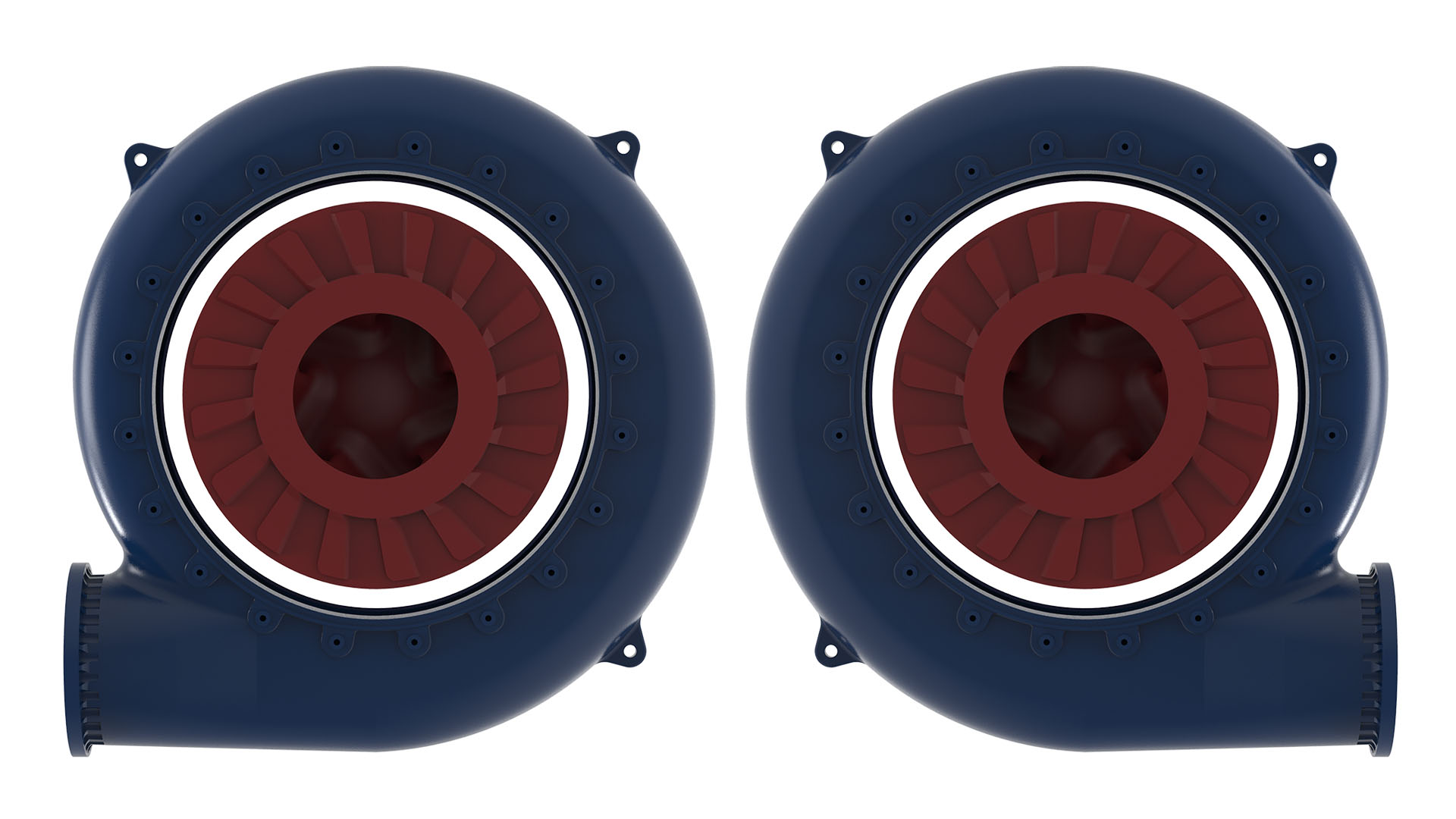

Symmetric casing design

Many customer sites have pumps rotating in both left- and right-hand orientations. This requires keeping different casings, liners and impellers in stock. Our UMD has a symmetric casing, which means for either orientation, it uses the same casing, suction liner, wear ring and back liner, reducing customer inventory requirements.

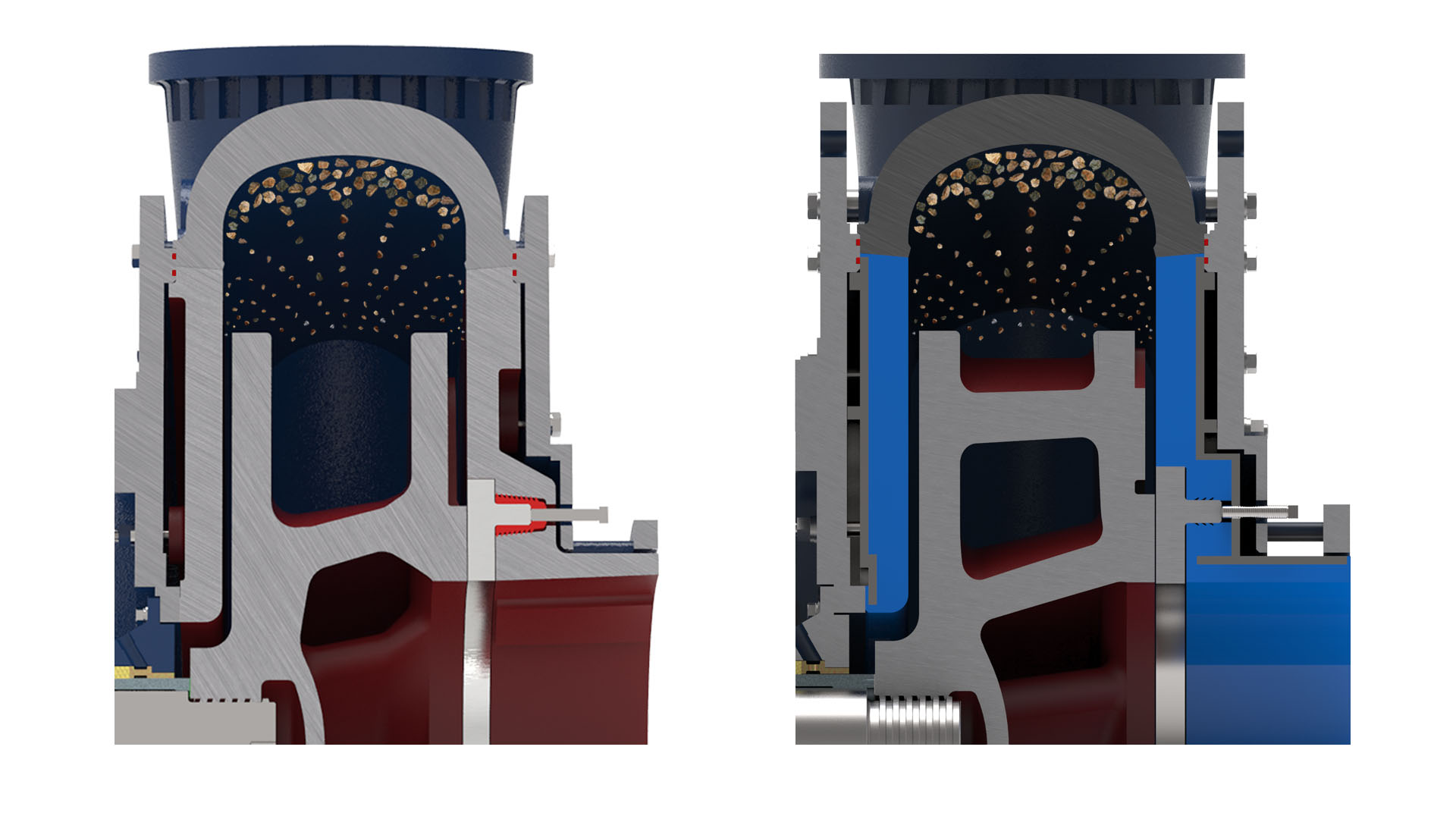

Large clearances

The UMD’s large clearance between the casing and impeller creates a deep bed of slurry that acts as a buffer zone, shielding the casing from the direct impact of coarse solids. An enlarged cutwater clearance reduces turbulence to extend pump life. Back and suction liners with oversized outer diameters protect the casing from high velocity and turbulence at the periphery of the impeller.

UMD-R elastomer lined pump

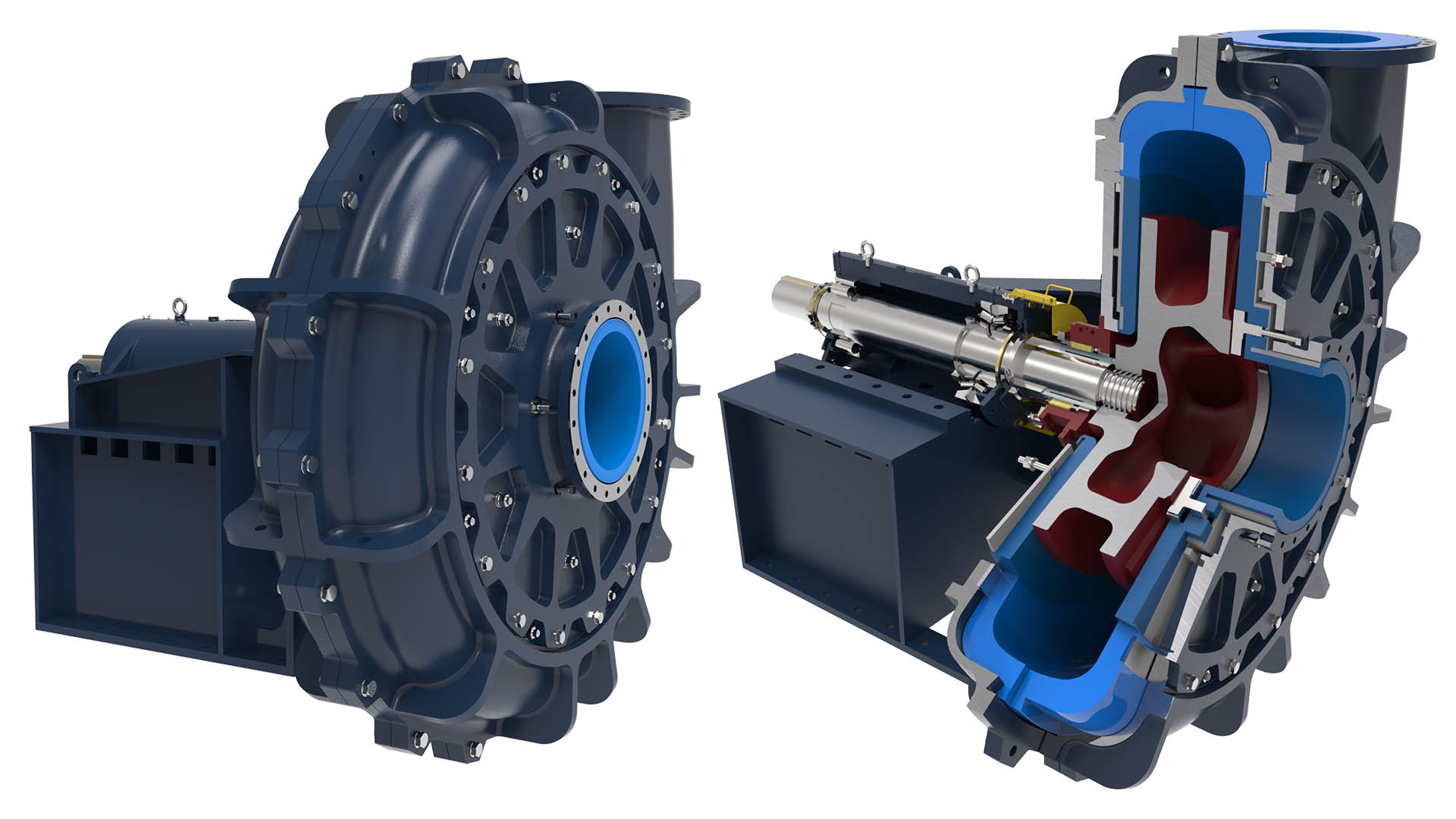

UMD-R elastomer lined pump

The UMD-R is a fully rubber lined, split case version of the UMD, designed for heavy-duty mill discharge applications. With heavy-duty rubber liners the UMD-R is particularly suited for wide flow ranges and corrosive duties.

SMART PUMPS - One simple app for better understanding and improving your operation

With the combination of our SiteConnect™ app and KREBS® Smart Pumps, you now have access to real-time information about your pumps on any phone or mobile device. Get instant alerts about operational deviations so that you know about potential problems before they occur. With better information about current operation, historical data, trends and advanced calculations, one simple app gives you a snapshot of the overall health of your entire plant. Learn more SiteConnect™ mobile app.